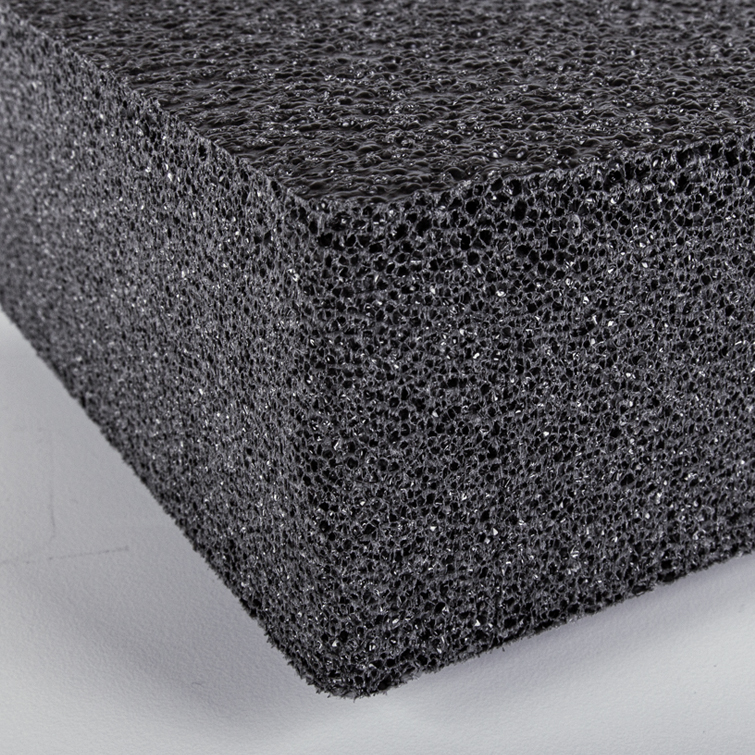

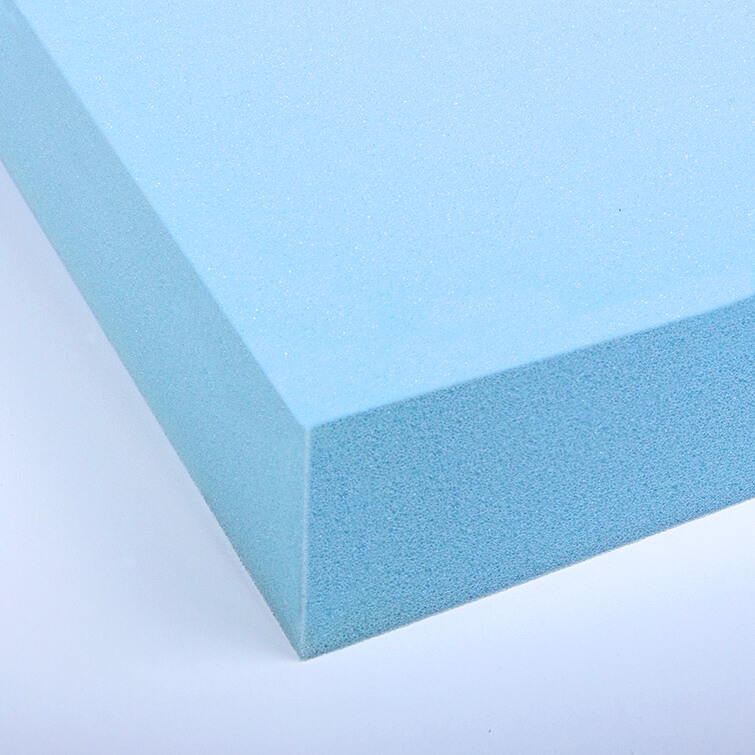

Polyurethane

![]()

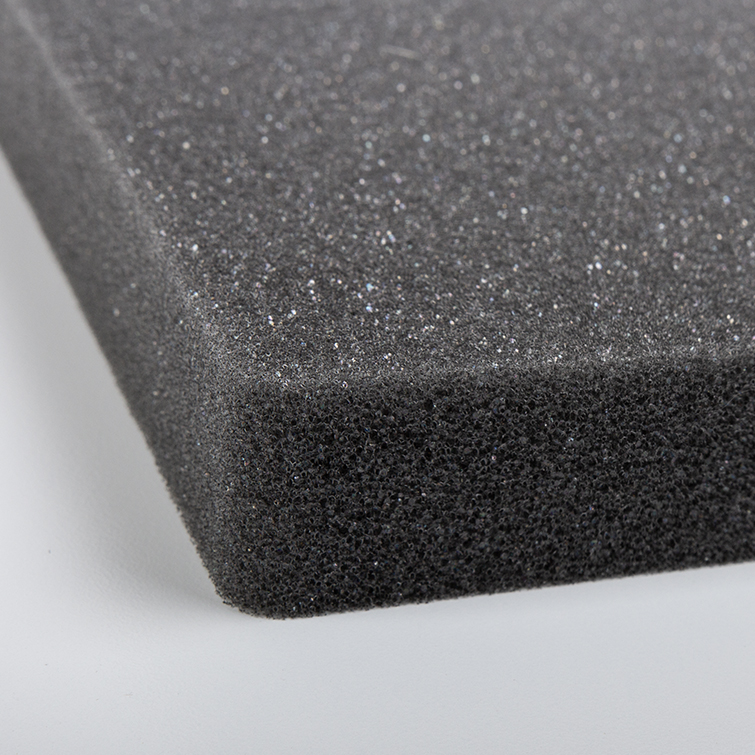

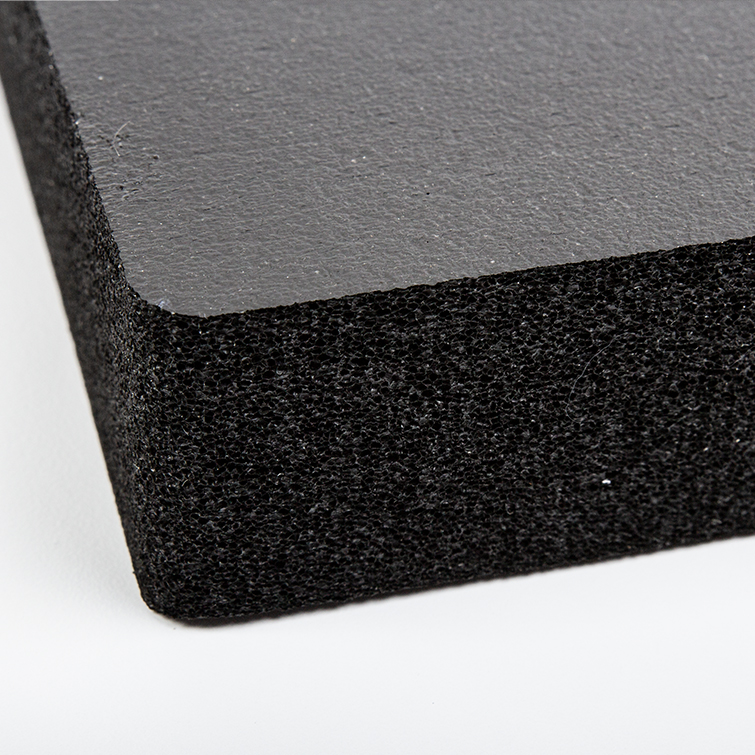

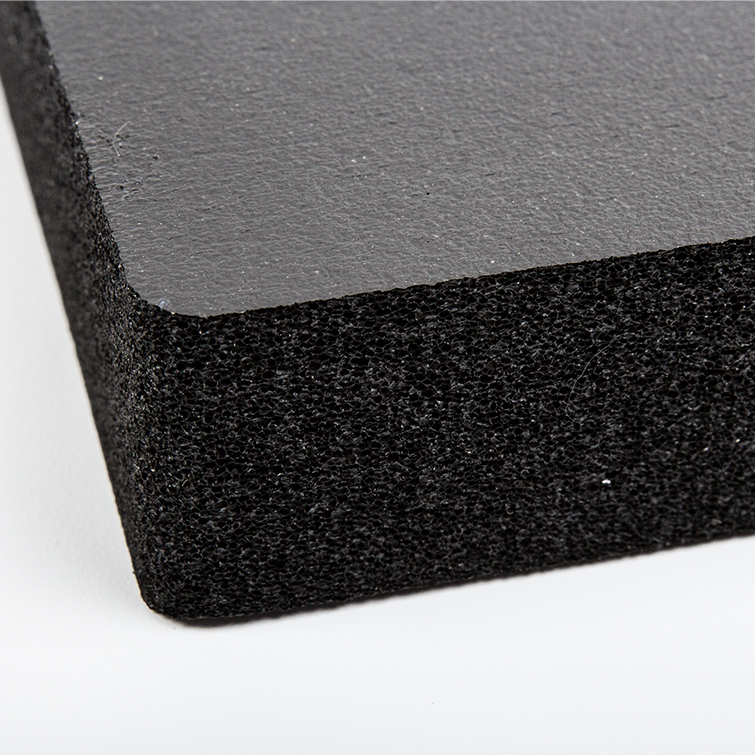

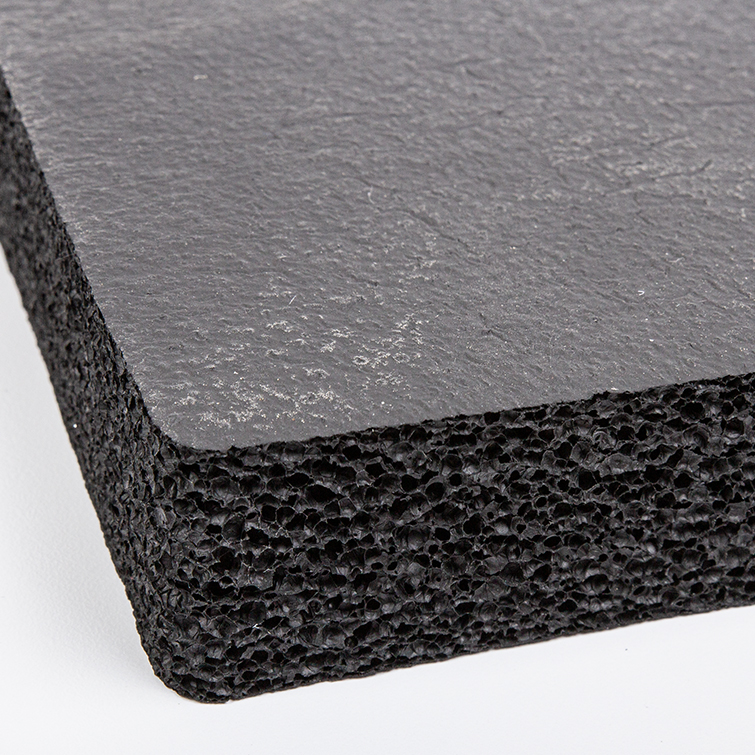

2 lbs. / ft.³ Flexible Polyester Urethane Sound Absorption Foam

Material # 16220

Primarily used for sound absorption, cushioning, vibration damping, and thermal insulation.

Tensile Strength : 15 psi min

Elongation : 160% min.

Tear Strength : 1 pli min.

Flammability : FMVSS302 Compliant

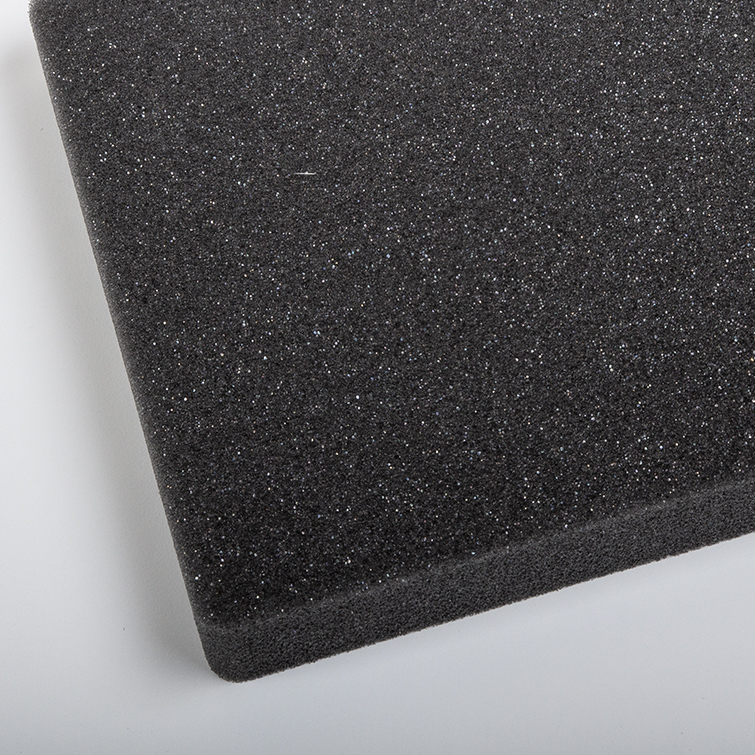

4 lbs. / ft.³ Flexible Polyester Urethane Sound Absorption Foam

Material # 16400

Primarily used for sound absorption, cushioning, vibration damping, and thermal insulation.

Tensile Strength : 12 psi min

Elongation : 120% min

Tear Strength : 1.3 pli min

Flammability : FMVSS302 Compliant

Flammability : UL94 HF-1 Certified @ 3 mm min.

![]()

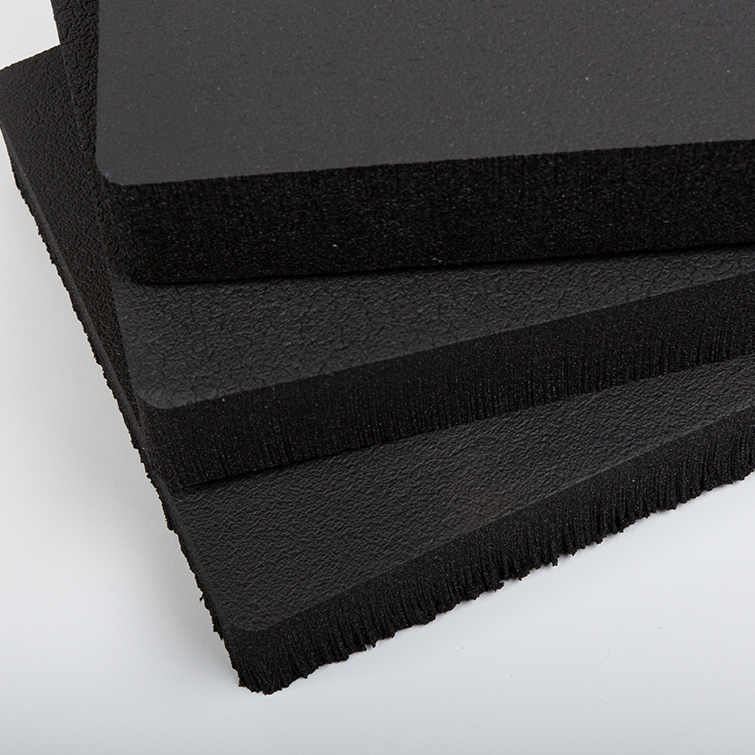

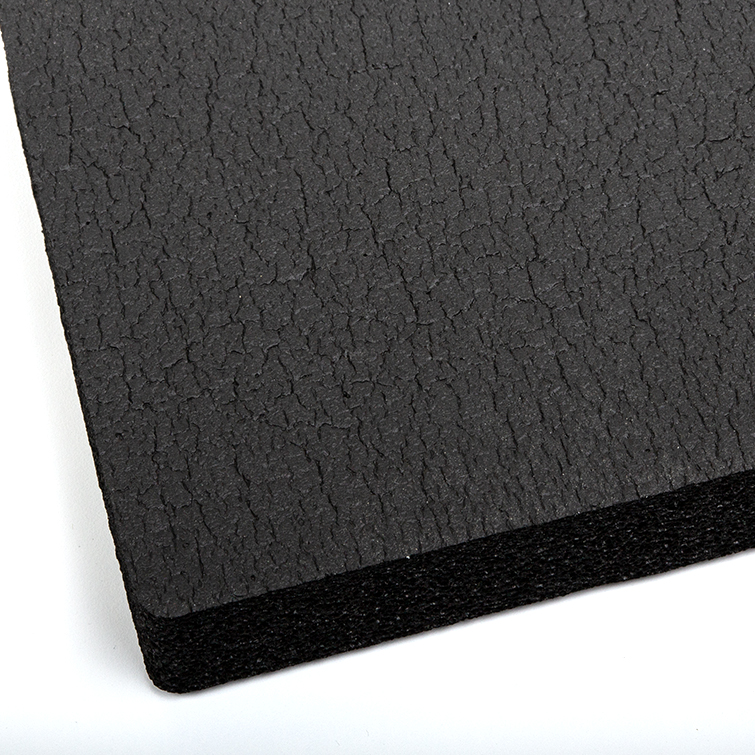

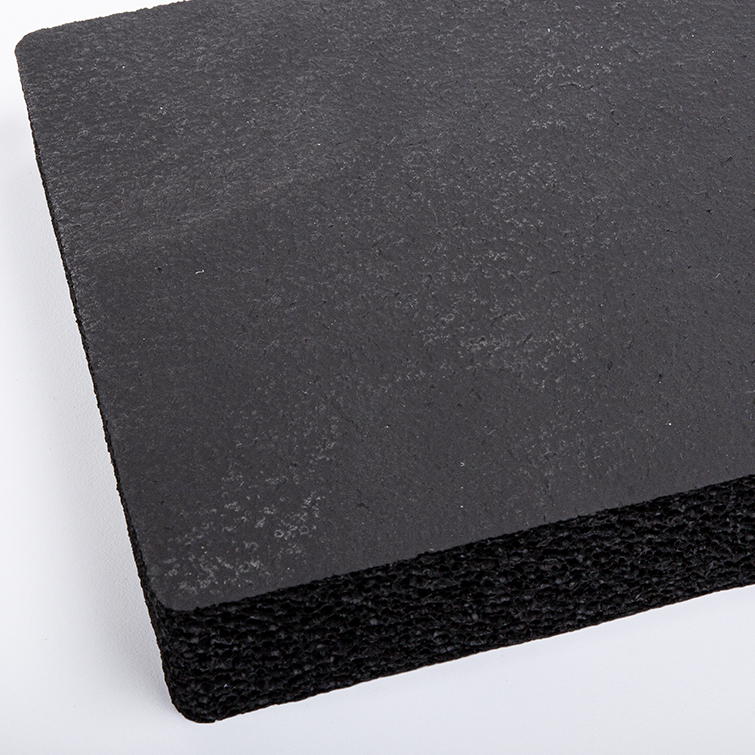

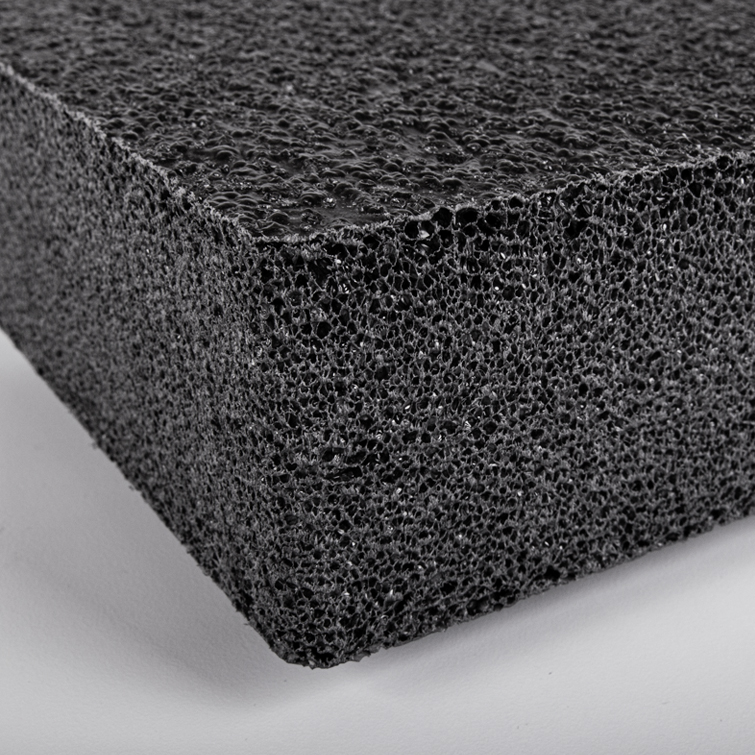

1.6 lbs. / ft.³ Flexible Polyether Urethane Sound Absorption Foam

Material # 17220

Primarily used for sound absorption and cushioning

Tensile Strength : 10 psi min

Elongation : 100% min

Tear Strength : 1 pli min

Flammability : FMVSS302 Compliant

1.65 lbs. / ft.³ Low Permeability Polyether Polyurethane Foam

Material # 17902

Primary used for air flow seals.

Tensile Strength : 10 psi min

Elongation : 120% min

Tear Strength : 1.5 pli min

Flammability : FMVSS302 Compliant

1.8 lbs. / ft³ Flexible Polyether Urethane Sound Absorption Foam

Material # 17180

Primarily used for sound absorption, cushioning, vibration damping, and thermal insulation

Tensile Strength : 12 psi min

Elongation : 140% min

Flammability : UL94 HF-1 Certified @ 3.3 mm min

Flammability : FMVSS302 Compliant

2 lbs. / ft.³ Flexible Low Permeability Polyether Urethane Foam

Material # 17900

Primarily used for air flow seals

Tensile Strength : 9 psi min

Elongation : 100% min

Tear Strength : 1 pli min

Flammability : FMVSS302 Compliant

2 lbs. / ft.³ Flexible Polyether Urethane Sound Absorption Foam

Material # 17610

Primarily used for sound absorption and cushioning

Tensile Strength : 9 psi min

Elongation : 140% min

Tear Strength : 1 pli min

Flammability : FMVSS302 Compliant

Flammability : UL94 HF-1 Certified @ 3mm min.

4 lbs. / ft.³ Flexible Polyether Urethane Sound Absorption Foam

Material # 17400

Primarily used for sound absorption and cushioning

Tensile Strength : 16 psi min

Elongation : 150% min

Tear Strength : 1.5 pli min

Flammability : FMVSS302 Compliant

Flammability : UL94 HF-1 Certified @ 6mm min

Closed-Cell

Expanded Neoprene / Vinyl / Nitrile Blend

Expanded Neoprene / PVC / Nitrile Blend 2B1 Foam

Material # 10100

Black, light density, closed-cell elastomeric product especially designed to perform where an inexpensive gasket or stripping material is required. This product is ideally suited for vibration isolation and damping, cushioning and padding, gasketing and sealing, and shock absorption.

Compression Deflection 25% : 2 – 5 psi

Compression Set (50%) : 30% max

Elongation : 75% min.

Flammability : UL94 HF-I Certified @ 3 mm

Flammability : UL94 V-0, 5VA Certified @ 6 mm

Flammability : FMVSS302 Certified

Service Temperature Range : - 40°F to 200°F

Expanded Neoprene / PVC / Nitrile Blend 2B2 Foam

Material # 10200

Black, light density, closed-cell elastomeric product especially designed to perform where an inexpensive gasket or stripping material is required. This product is ideally suited for vibration isolation and damping, cushioning and padding, gasketing and sealing, and shock absorption.

Compression Deflection 25% : 5 – 9 psi

Compression Set (50%) : 35% max

Elongation : 75% min.

Flammability : FMVSS302 Certified

Flammability : UL94 HF-1 Certified @ 3.4 mm

Service Temperature Range : - 40°F to 200°F

Expanded Neoprene / PVC / Nitrile Blend 2B3 Foam

Material # 10300

Black, light density, closed-cell elastomeric product especially designed to perform where an inexpensive gasket or stripping material is required. 10300 is an efficient thermal insulator and can be used where there are no specific requirements for flame resistance or smoke generation. This product is ideally suited for vibration isolation and damping, cushioning and padding, gasketing and sealing, and shock absorption.

Compression Deflection 25% : 9 – 13 psi

Compression Set (50%) : 35% max

Elongation : 100% min

Flammability : Certified @ 3.0 mm | Certified @ 6.0 mm | Certified

Service Temperature Range : - 40°F to 200°F

Crushed Neoprene / Vinyl / Nitrile Blend

Crushed PVC / Nitrile Blend Super Soft 1A0 Foam

Material # 10410

Crushed cell foam that works well in gasket applications where conforming to irregular surfaces is required and when easy compressibility is a necessity. When compressed to 50% of its original thickness, the material will form a watertight seal.

Compression Deflection 25% : .4 psi max

Compression Set (50%) : 5% max

Elongation : 100% min

Flammability : FMVSS302 Certified

Service Temperature Range : - 40°F to 200°F

Expanded EPDM

Expanded EPDM 2A1 Foam

Material # 20001

Closed cell synthetic rubber used in insulation, vibration damping, noise damping, gasket, and seal applications. It has excellent outdoor aging characteristics and ozone resistance.

Compression Deflection 25% : 2 – 5 psi

Compression Set (50%) : 40% max

Elongation : 175% min.

Flammability : FMVSS302 Certified at .1875" and thicker

Service Temperature Range : - 70°F to 250°F

Crushed EPDM

Crushed EPDM 1A0 Foam

Material # 20410

Crushed cell foam that works well in gasket applications where conforming to irregular surfaces is required and when easy compressibility is a necessity. Because it is made from EPDM polymer, it offers a greater service temperature range and excellent resistance to weathering versus PVC/NBR.

Compression Deflection 25% : 1 psi max

Compression Set (50%) : 35% max

Elongation : 200% min

Flammability : FMVSS302 Certified

Service Temperature Range : - 65°F to 250°F

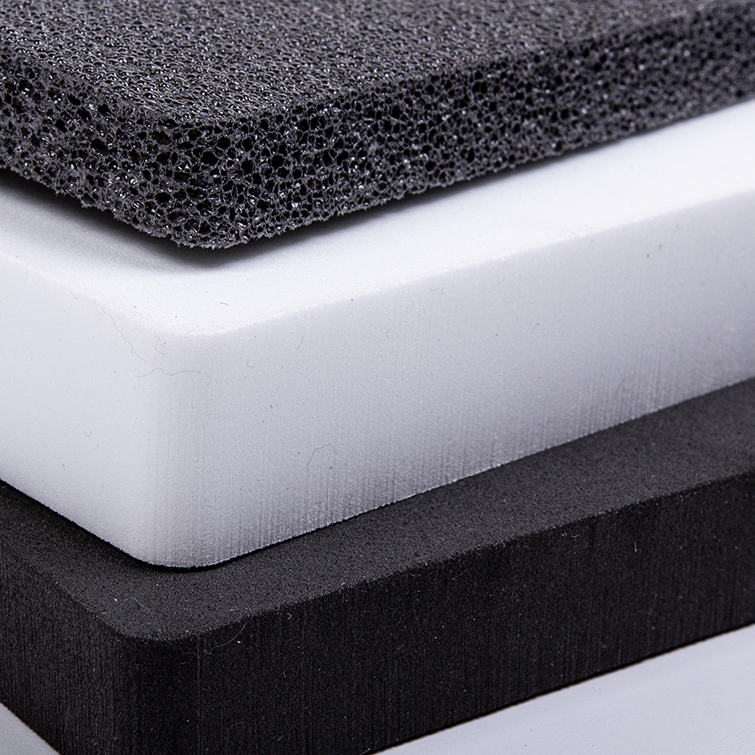

Crosslinked Polyethylene

2 lbs. / ft.³ Crosslinked Polyethylene Fine Cell Foam

Material # 29001

Soft, aesthetically pleasing materials offering superior flexibility, elasticity and resiliency. They exhibit exceptional mechanical strength and durability. These materials can be cut, slit, die cut, skived, sewn, embossed, vinyl dipped and adhesive coated and are ideal for heat and adhesive lamination to a variety of materials including metals, plastic films and most textiles.

Compression Set (50%) : 40% max

Elongation : 100% min

Flammability : FMVSS302 Certified at >.25” (6.35 mm) thickness

Service Temperature Range : - 40°F to 210°F

2 lbs. / ft.³ Crosslinked Polyethylene Coarse Cell Foam

Material # 29500

Skin-soft aesthetically pleasing material offering superior flexibility, elasticity and resiliency. It exhibits exceptional mechanical strength and durability. Can be cut, slit, die cut, skived, sewn, embossed, vinyl dipped and pressure sensitive coated. It is an ideal material for heat, adhesive, ultrasonic or radio frequency (RF) lamination to a variety of materials including metals, plastic films and most textiles. It’s primary functions are thermal insulation, seals, and gaskets

Compression Deflection 25% : 4 – 8 psi

Compression Set (50%) : 30% max

Elongation : 85% min

Flammability : FMVSS302 Certified at >.25” (6.35 mm) thickness

Service Temperature Range : - 40°F to 175°F

6 lbs. / ft.³ Crosslinked Polyethylene Fine Cell Foam

Material # 29600

Firm, aesthetically pleasing material exhibiting exceptional mechanical strengthand durability.These materialscan be cut, slit, die cut, skived,embossed, vinyl dipped and adhesive coatedand areideal for heat and adhesive lamination to a variety of materials including metals, plastic films andmost textiles.

Elongation : 145% min

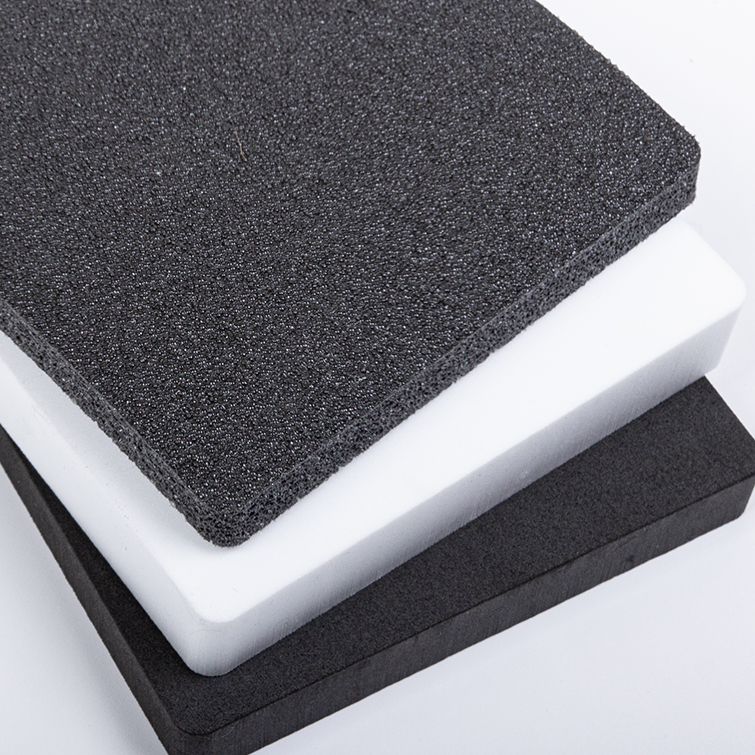

Expanded Polyethylene

2 lbs. / ft.³ Expanded Polyethylene Foam

Material # 28550

Soft low cost foam can be used for packaging and gap filling applications. It can be cut, split, diecut, skived, and laminated.

Compression Set (50%) : 12.4% max

6 lbs. / ft.³ Expanded Polyethylene Foam

Material # 29120

Firm low cost foam can be used for packaging and gap filling applications. It can be cut, split, diecut, skived, and laminated.

Compression Set (50%) : 25% max

9 lbs. / ft.³ Expanded Polyethylene Foam

Material # 29125

Extra Firm low cost foam can be used for packaging and gap filling applications. It can be cut, split, diecut, skived, and laminated.

Compression Set (50%) : 25% max

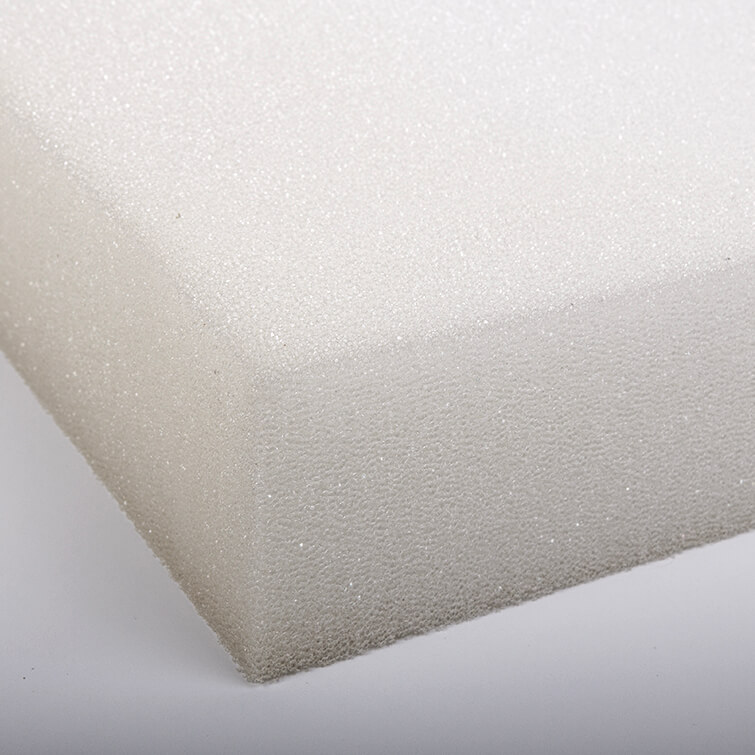

Flexible

Conventional

1# 30 IFD Flexible Polyether Open-Cell Foam

Known for its comfort and cushioning properties, this foam product is commonly used in applications such as seating, packaging, marine / boating and matting.

Density : .95 – 1.05 lbs. / ft.³

Indentation Force Deflection : 27 – 33 lbs. / 50 sq. in.

Elongation : > 100%

Tear Strength : > 1 lbs. / in.

Flammability : Cal 117-2013

1.2# 34 IFD Flexible Polyether Open-Cell Foam

Known for its comfort and cushioning properties, this foam product is commonly used in applications such as seating, packaging, marine / boating and matting.

Density : 1.15 – 1.25 lbs. / ft.³

Indentation Force Deflection : 31 – 37 lbs. / 50 sq. in.

Elongation : > 100%

Tear Strength : > 1.2 lbs. / in.

Flammability : Cal 117-2013

1.25# 36 IFD Polyether Antimicrobial Foam

Known for its comfort, cushioning and antimicrobial properties, this foam product is commonly used in applications such as seating, packaging, marine / boating and matting.

Density : 1.15 – 1.35 lbs. / ft.³

Indentation Force Deflection : 33 – 39 lbs. / 50 sq. in.

Elongation : > 100%

Tear Strength : > 1 lbs. / lin. in

Flammability : Cal 117-2013

1.45# 50 IFD Polyether Antimicrobial Foam

Known for its comfort, cushioning and antimicrobial properties, this foam product is commonly used in applications such as seating, packaging, marine / boating and matting.

Density : 1.35 – 1.55 lbs. / ft.³

Indentation Force Deflection : 45 – 55 lbs. / 50 sq. in.

Elongation : > 100%

Tear Strength : > 1 lbs. / in.

Flammability : Cal 117-2013

1.8# 28 IFD Flexible Polyether Open-Cell Foam

Known for its comfort and cushioning properties, this foam product is commonly used in applications such as seating, packaging, marine / boating and matting.

Density : 1.7 – 1.85 lbs. / ft.³

Indentation Force Deflection : 25 – 31 lbs. / 50 sq. in.

Elongation : > 125%

Tear Strength : > 1 lbs. / in

Flammability : NFPA 260 Class I

1.8# 36 IFD Polyether Antimicrobial Foam

Material # 17445

Known for its comfort, cushioning and antimicrobial properties, this foam product is commonly used in applications such as seating, packaging, marine / boating and matting.

Density : 1.7 – 1.9 lbs. / ft.³

Indentation Force Deflection : 32 – 40 lbs. / 50 sq. in.

Elongation : > 100%

Tear Strength : > 1 lbs. / in.

Flammability : Cal 117-2013

1.8# 45 IFD Polyether Urethane Foam

Material # 17450

Known for its comfort and cushioning properties, this foam product is commonly used in applications such as seating, packaging, marine / boating and matting.

Density : 1.75 – 1.85 lbs. / ft.³

Indentation Force Deflection : 42 – 48 lbs. / 50 sq. in

Elongation : > 130%

Tear Strength : > 1.3 lbs. / in.

Flammability : Cal 117-2013

1.8# 60 IFD Polyether Urethane Foam

Material # 17460

Known for its comfort and cushioning properties, this foam product is commonly used in applications such as seating, packaging, marine / boating and matting.

Density : 1.75 – 1.85 lbs. / ft.3

Indentation Force Deflection : 57 – 63 lbs. / 50 sq. in.

Elongation : >130%

Tear Strength : > 1.3 lbs. / in.

Flammability : Pass

High Resilient

2.2# 29 IFD Flexible Polyether Open-Cell Antimicrobial Foam

Material # 17806

This open-cell flexible polyurethane foam has a high-resilient (HR) prefix, which designates this as a high resilience product. The cell structure and specialty raw materials used provide higher flexibility than other conventional foams. Common applications include cushioning for consumer bedding / pillows, as well as medical mattresses.

Density : 2 – 2.4 lbs. / ft.³

Indentation Force Deflection : 26 – 32 lbs. / 50 sq. in

Elongation : > 90%

Tear Strength : > .9 lbs. / in

Flammability : Cal 117-2013

2.7# 24 IFD Flexible Polyether Open-Cell High Resilient Foam

Material # 17814

This open-cell flexible polyurethane foam has a high-resilient (HR) prefix, which designates this as a high resilience product. The cell structure and specialty raw materials used provide higher flexibility than other conventional foams. Common applications include cushioning for consumer bedding / pillows, as well as medical mattresses.

Density : 2.6 – 2.8 lbs. / ft.³

Indentation Force Deflection : 21 – 27 lbs. / 50 sq. in

Elongation : > 100%

Tear Strength : > 1 lbs. / in

Flammability : Cal 117-2013

Flammability : FMVSS302

3.1# 33 IFD Flexible Polyether Open-Cell High Resilient Foam

Material # 17810

This open-cell flexible polyurethane foam has a high-resilient (HR) prefix, which designates this as a high resilience product. The cell structure and specialty raw materials used provide higher flexibility than other conventional foams. Common applications include cushioning for consumer bedding / pillows, as well as medical mattresses.

Density : 2.8 – 3.4 lbs. / ft.³

Indentation Force Deflection : 30 – 36 lbs. / 50 sq. in.

Elongation : > 90%

Tear Strength : >1.50 lbs. / in.

Flammability : Cal 117-2013

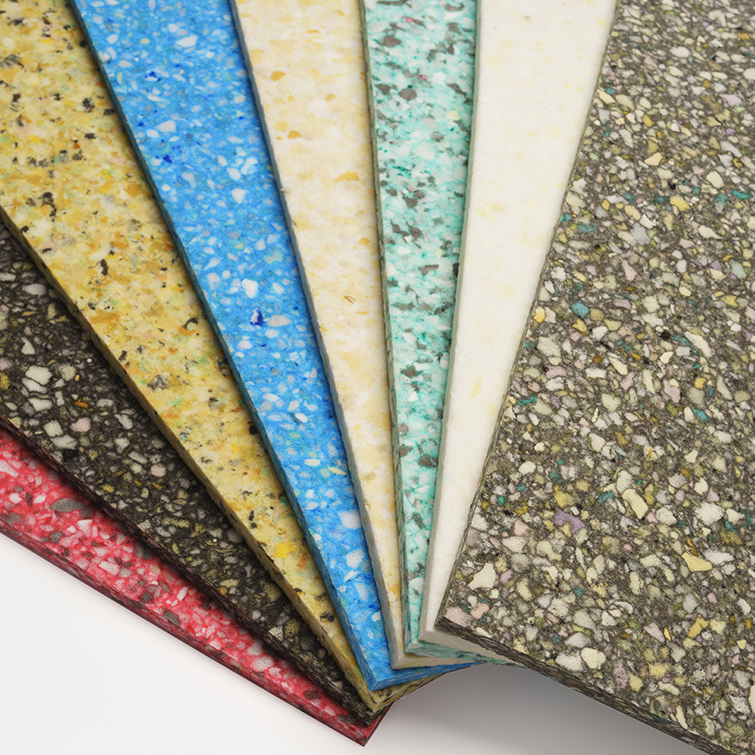

Rebond Foam

8# Heavy Traffic Class II Rebond Carpet

Material # 17886

This rebond foam product is known for its cushioning and matting properties and applications, composed of recycled foam materials.

Density : 8 lbs. / ft.³

10# Rebond Urethane Foam

Material # 17895

This rebond foam product is known for its cushioning and matting properties and applications, composed of recycled foam materials.

Density : 10 lbs. / ft. ³

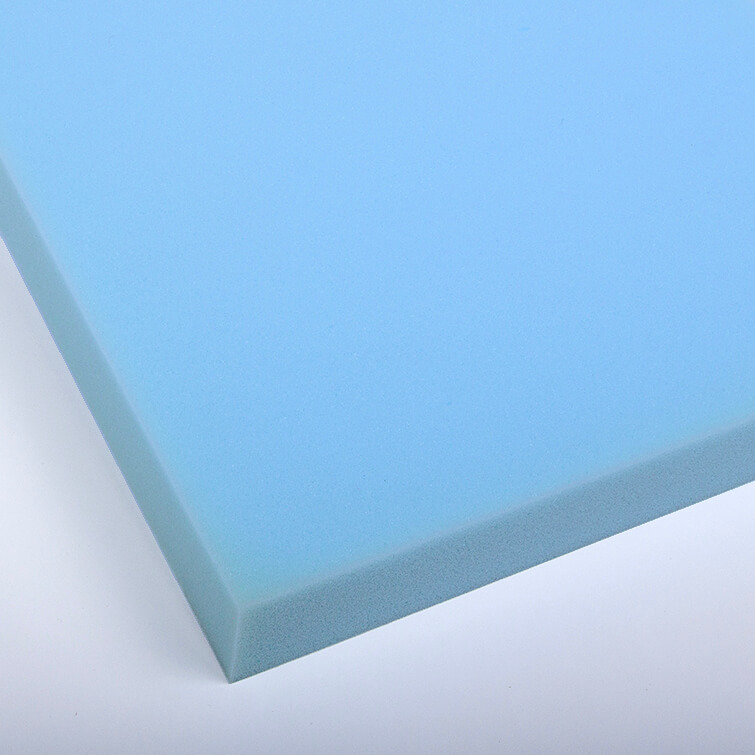

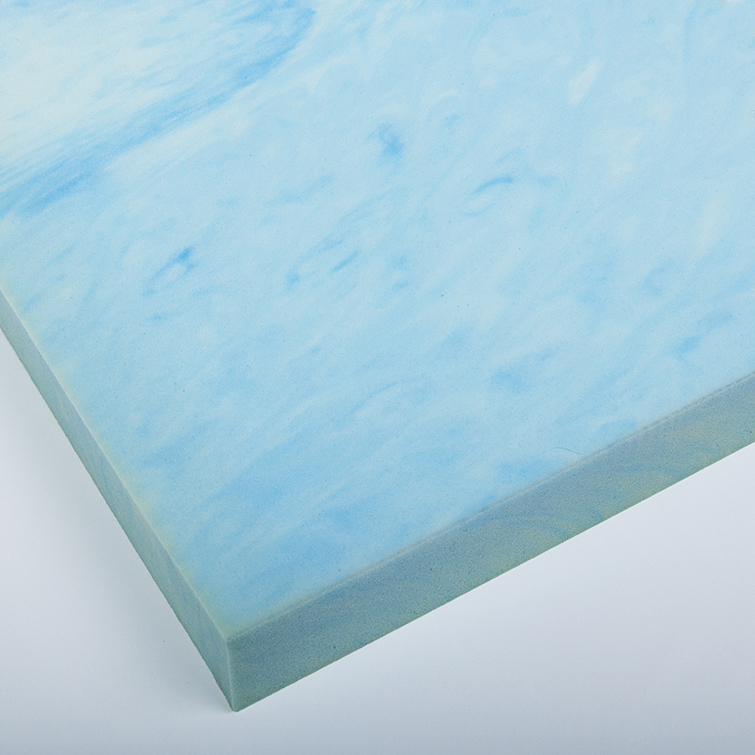

Memory Foam

4# Visco Elastic Memory Foam with Blue Swirl Cooling Gel

Material # 17750

This visco elastic memory foam returns to its original shape and size slowly after release from compression, exhibiting a low degree of resiliency when tested with conventional ball rebound testing. The gel additive provides improved physical properties and a comforting, cool feeling.

Density : 3.7 – 4.3 lbs. / ft.³

Indentation Force Deflection : 11 – 17 lbs. / 50 sq. in

Elongation : > 100%

Tear Strength : > .8 lbs. / lin. in

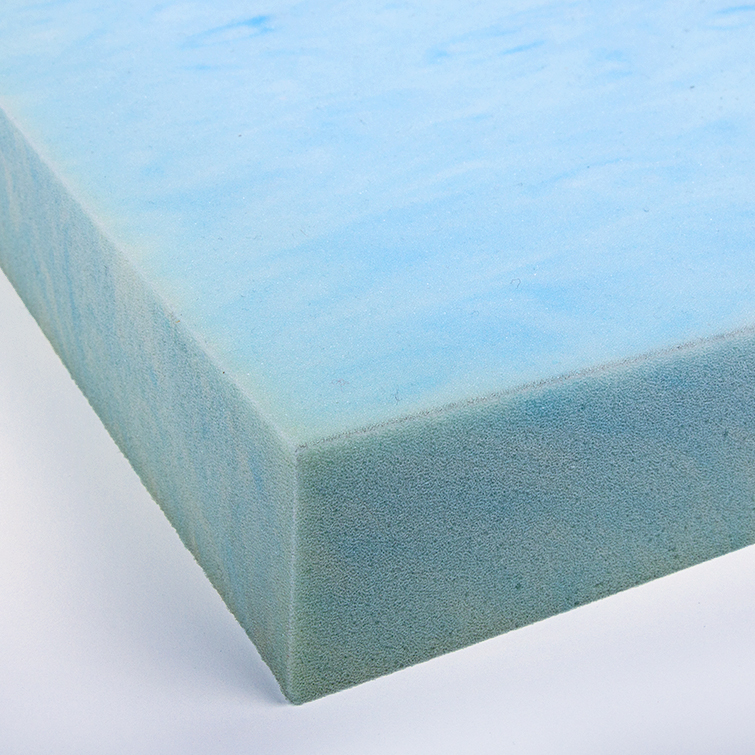

2.4# Visco Elastic Memory Foam

Material # 17767/17768

This visco elastic memory foam returns to its original shape and size slowly after release from compression, exhibiting a low degree of resiliency when tested with conventional ball rebound testing.

Density : 2.2 – 2.6 lbs. / ft.³

Indentation Force Deflection : 8 – 11 lbs. / ft. ³

Reticulated Foam

1.8# 15 IFD Super Soft Reticulated Foam

Reticulated foam is a fast-drying open-cell foam with breathability for water and air to easily pass through the material, making it an ideal solution for outdoor cushioning applications and other uses.

Density : 1.7 – 1.9 lbs. / ft. ³

Indentation Force Deflection : 12.5 – 17.5 lbs. / ft. ³

Elongation : >225%

Tear Strength : 8.56 lbs. min.

Flammability : Cal 117-2013

1.8# 35 IFD Medium Reticulated Foam

Reticulated foam is a fast-drying open-cell foam with breathability for water and air to easily pass through the material, making it an ideal solution for outdoor cushioning applications and other uses.

Density : 1.7 – 1.9 lbs. / ft. ³

Indentation Force Deflection : 32.5 – 37.5 lbs. / ft. ³

Elongation : >225%

Tear Strength : 5.5 lbs. min

Flammability : Cal 117-2013

1.8# 65 IFD Firmer Reticulated Foam

Reticulated foam is a fast-drying open-cell foam with breathability for water and air to easily pass through the material, making it an ideal solution for outdoor cushioning applications and other uses.

Density : 1.7 – 1.9 lbs. / ft. ³

Indentation Force Deflection : 62.5 – 67.5 lbs. / ft. ³

Elongation : >150%

Tear Strength : 5 lbs. min

Flammability : Cal 117-2013